The Basic Principles Of Retaining Wall Inspections

Wiki Article

All About Retaining Wall Inspections

Table of ContentsThe Definitive Guide to Retaining Wall InspectionsSome Ideas on Retaining Wall Inspections You Need To KnowThe Buzz on Retaining Wall InspectionsRetaining Wall Inspections for DummiesFascination About Retaining Wall Inspections

WMT&R can examine numerous sorts of materials consisting of: Composites, Carbon-Fiber, Ceramic Matrix Composites, Titanium, Polymers, Common Steels, 4340 Steel, Stainless Steels, A2 Tool Steel, Inconel 718, Aluminum 7050, as well as Aluminum Lithium 2195, as well as many others. retaining wall inspections. WMT&R additionally examination products created utilizing Additive Production/ 3d printing, Bolts, finished products and also components including aluminum castings as well as extrusions. At Westmoreland Mechanical Testing & Research, Inc (WMT&R) Stress and also Compression examinations are conducted on a remarkable series of machines with capacities from 10 grams to 1,000,000 lbs. Evaluating is carried out in different environments (Argon, Vacuum Cleaner, Corrosive Mediums) at cryogenic, ambient, as well as raised temperature levels (-450 F to +2200 F). Our exclusive screening software provides the capability to run conventional tests plus full stress/full stress tests at various strain rates, crosshead speeds, load ranges, and pressure arrays as your needs need.

WMT&R assesses the procedure of modern local permanent architectural change happening in a product subjected to problems that produce rising and fall anxieties and stress at some point or factors. These tensions and also strains may finish in cracks or total crack after an adequate number of changes. WMT&R has a large variety of machine and also fixtures with the ability of custom-made configurations and also fixtures.

Retaining Wall Inspections Things To Know Before You Get This

Temperature as well as creep readings are taped by computers and also continuously monitored to insure miraculous accuracy. The Stress as well as Creep screening lab residences 500 Stress and anxiety Tear and Creep Test machines, providing 30,000 pound. capacity capability, a specialist engineering personnel and Nadcap-approval. Mechanical Engineering, The Mechanical Design laboratory at Westmoreland Mechanical Testing & Study, Inc (WMT&R) is staffed by specialists as well as designers in product analysis of actual prototype elements and also subassemblies.

Factory The high-technology, full-service Machine Shop at Westmoreland Mechanical Testing & Research Study, Inc (WMT&R) incorporates a clean, temperature-controlled environment, advanced equipment, as well as the capacity to equipment all test specimens onsite. In addition to machining common samplings, our Factory can custom-design and machine fixtures for testing finished parts, odd shapes, and difficult or exotic materials.

Fascination About Retaining Wall Inspections

With sophisticated internal capacities, as well as considerable engineering experience, WMT&R are specialists in low-stress grinding as well as machining sub dimension samplings to extremely close tolerances. Thermal Evaluation refers to the variety of techniques created as well as used in which any kind of physical home of a given product/system is learn this here now continuously gauged as a function of temperature.WMT&R uses numerous methods including; Dilatometry (DIL), Laser Flash Evaluation, Dynamic Mechanical Analysis (DMA), Thermomechanical Evaluation (TMA), Differential Scanning Calorimetry (DSC) and Thermogravimetry (TGA). retaining wall inspections. The Thermal Evaluation abilities at Westmoreland Mechanical Screening & research study, Inc. can reinforce the depth and also high quality of screening results guaranteeing products have the ability to endure its intended application.

Our experienced professionals and metallurgists function closely with the analytical and also physical testing groups to provide an of material attributes so that even one of the most difficult issues can be recognized and fixed promptly. Services consist of, basic microstructure, macro/grain flow, alpha situation, mini solidity, fractography, grain size, IGA/IGO/decaburization as well as even more.

The smart Trick of Retaining Wall Inspections That Nobody is Talking About

Westmoreland Mechanical Screening & Study, Inc (WMT&R) is a top quality Chemical and also Analytical Screening Research laboratory making use of definitive spectrometer technology. Working in combination with ICP and also Graphite Heater AA makes certain fast turn-around by removing the requirement additional hints for prolonged wet chemical tests. These cutting-edge systems offer enhanced analysis rate, component arrays, as well as sensitivity.Westmoreland Mechanical Testing & Research Study, Inc (WMT&R) has a worldwide credibility for reliable fracture toughness screening. The advanced fracture lab is made for the high quantity, quick turnaround tasks demanded by the aerospace, automobile, power generation, oil & gas, additive manufacturing and also clinical industries. WMT&R's fracture strength and also exhaustion materials testing research laboratory homes an expansive variety of maker as well as components with the ability of 1 million lb.

Evaluating consists of ASTM E399 which provides disc form, arc tension, arc bend, single-edge bend, as well as portable tension. Regarding small stress testing, WMT&R is furnished to perform products examining on sizes varying from. 25" thick, up to 4. 25" thick for a lot of applications and also has machined as well as examined steel compact stress samplings up to 8" thick evaluating 1,000 pounds.

The Ultimate Guide To Retaining Wall Inspections

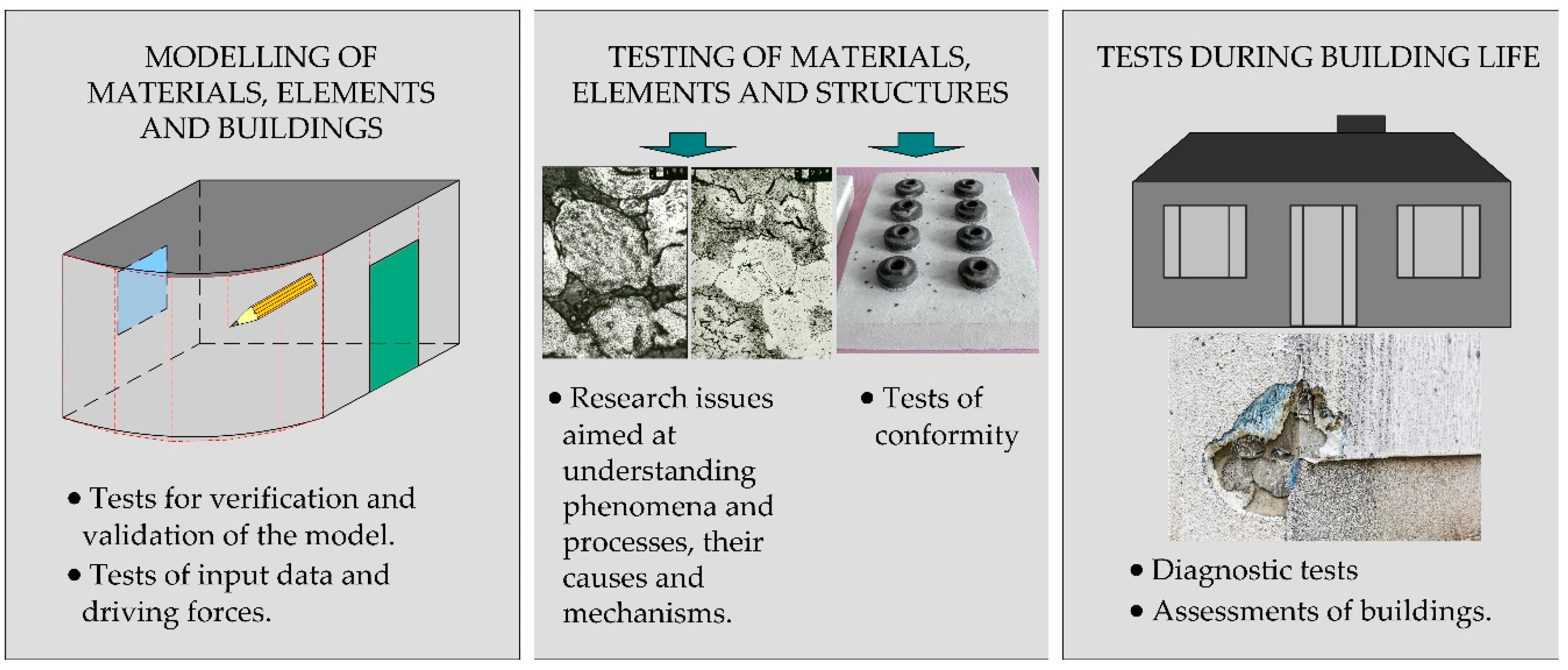

With over half a century of products examining experience, and also vital Nadcap and also A2LA certifications, Westmoreland Mechanical Screening & Study, Inc (WMT&R) is distinctly certified to examine products produced you could check here utilizing additive manufacturing processes. Westmoreland Mechanical Testing & Research, Inc (WMT&R) is a trusted materials evaluating partner for the aerospace primes and also various other business in sophisticated industries such as automotive, clinical, and also power generation who are leading the adoption of these products as well as processes.Products screening, measurement of the characteristics as well as actions of such materials as steels, ceramics, or plastics under numerous conditions. The data therefore acquired can be made use of in specifying the viability of products for numerous applicationse.

For producers, it is of the utmost relevance to comprehend the mechanical buildings of materials that show some Hookean habits throughout loading. It is very important because the performance of a framework is frequently figured out by the amount of contortion allowed. Materials are examined for diverse functions: to determine the residential properties of the raw material, to inspect top quality at intermediate phases in manufacturing processes, to inspect completed products, as well as to assist research.

Report this wiki page